Automotive Diagnostics

The automotive diagnostic market, with the increasing electronic of automobiles, has seen more and more frequent scenarios in which fault determination is made by reading data in automotive maintenance. Especially now with the development of electric vehicles, almost 80% of the maintenance is concentrated on the central data system. The importance of diagnostic equipment is increasing, and diagnostic equipment directly affects work efficiency and business revenue. The traditional practice in the past was to perform related operations by connecting the laptop to the CAN of the car, but nowadays, with more and more frequent reading operations, the weakness of the laptop as the main device becomes obvious.

Military-grade ruggedness solves the problem of easy damage

Unione's 17 years of experience in rugged terminal equipment and professional structural design ensure that the equipment is resistant to drops, vibration, dust and water. 1.2m concrete drop resistance, IP67 protection, and high and low temperature adaptability from -20 degrees to 60 degrees, comprehensively solving the dilemma of easy damage to the equipment.

Long equipment life cycle

Product development and design by 5-year life cycle, selection of core components with ultra-long life cycle to ensure continuous and stable output of a single model within 5 years, never worry about equipment management and maintenance.

Grand Slam Communications and Interfaces

The special nature of automotive diagnosis, our device has a grand slam of communication, Wifi, Bluetooth, 4G as well as GPS, Compass and Galileo positioning, which makes it easy to handle even in the field for emergency repairs. The front camera can clearly shoot the failure point and make video communication support, so you can quickly ask for help. Multiple USB ports and Type C ports are supported .

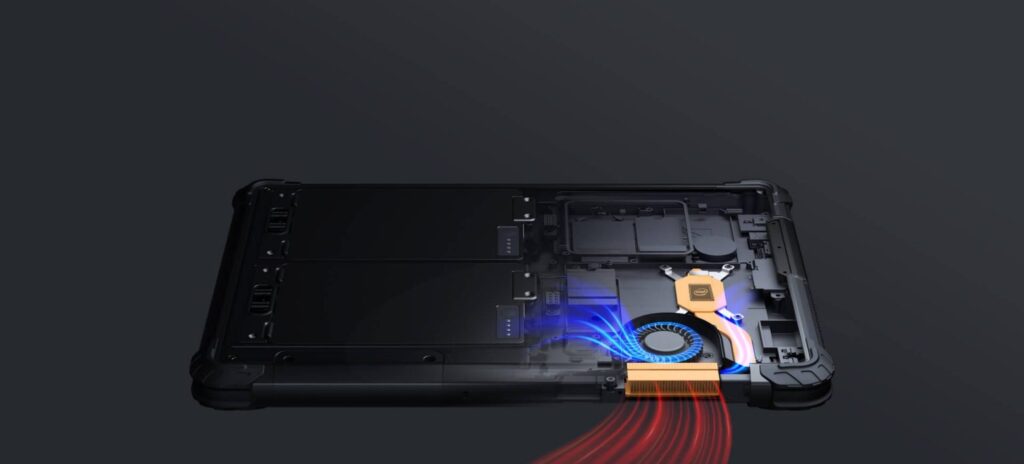

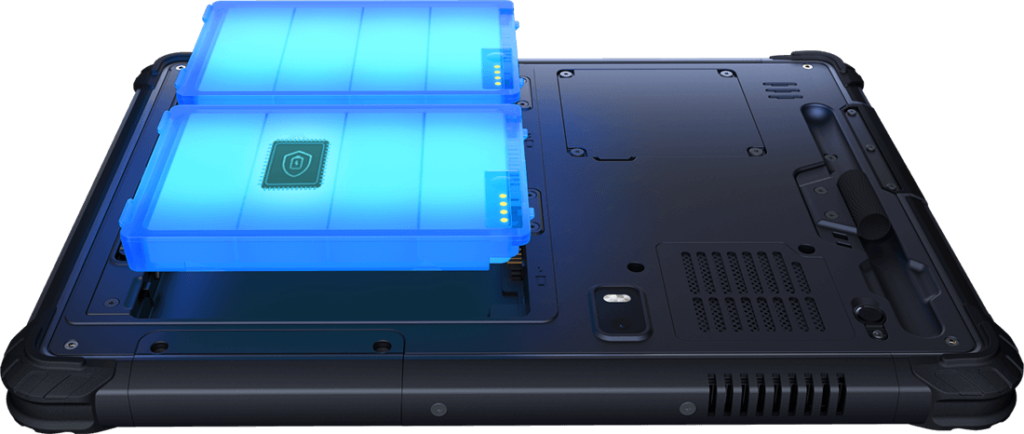

Interchangeable modules

The pioneering replaceable interface module solves the high maintenance costs and reduced work efficiency caused by damaged interfaces in automotive diagnostics. When the interface is damaged, the user can quickly replace the bad parts with a screwdriver and 1 minute. It will not affect the normal workflow at all, and the equipment maintenance cost is reduced by 70%.

Reduction of equipment procurement costs

The price of a regular tablet is lower than that of a rugged tablet, which is a major reason why many people choose a regular tablet + case. Is this really the case? If we look at the cost of a single purchase, it is indeed cheaper. But if we look at the whole picture of the entire life cycle of 3-5 years, we will find that the cost of a normal flat panel is 3 times the cost of a rugged flat panel. So what's the problem? The rugged flat panel is almost a one-off, with very low after-sales maintenance, improved performance, and less need for maintenance of the equipment. The cost of a repair is much more than the cost of the equipment itself, the work that is delayed is the cost, the manpower responsible for the repair is the cost, and when these costs are pooled together, you will find that the cost is so large. Finally, let's take a look at Unione's rugged tablet for the automotive diagnostic market, which you may have already seen in brick-andmortar 4S stores, where it has been used in more than 1,000 4S stores nationwide.