UniOne Test Laboratory Gallery

Salt Spray test

UniOne production center could perform the salt-spray test. The purpose of this test is to check the salt-spray resistance ability. If the device is not working properly in salty condition, UniOne R&D team will review test result comprehensively and improve the mechanical design until meeting the approval standard of corrosion.

Artificial sweat test

As we all know, the users use the device in summer. Sometimes the users ` hands is covered with a lot of sweat. With the time increasing, the sweat will gather lots of big beats of sweat. Then, the beats of sweat will drop it on screen. Maybe it will come in the gap of device or somewhere can get in internal of device. The sweat is acid, it can corrode the device. So we need make an environment like this, to verify the sweat whether is hard to device.

Temperature test

We have different modes and professional lab instruments to perform. The GDJS will generate high temperature and humid heat condition for test samples. One of another instrument will switch into constant temperature and humid heat condition. This aim is to verify the device can work on hostile temperature. It can praised by consumers that often work in and out

ESD test

Electrostatic fundamental experiments.

The electrostatic phenomenon is very common but could potentially impact some industrial users. The device shell is plastic. If it is not good connection group, the device will gather huge electric and it can cause accident in some dangerous or hazardous site. This experiment test is needed to give us a safe answer.

Abrasion resistance

We test all areas of the device but we perform more testings on the edge and back of the device. According the habit of customer, the edge and back device usually is worn out firstly. In order to improve this painpoint, we have the abrasion test to check the resistance of device. It is not only for nice appearance, it can ensure the safety of device in using process.

Drop test

Some people call it random drop test. UniOne provides kinds of machine to do the drop test .the most common has too many unregularly barrier in this machine. The high is like the people height to imitate the case when device dropping from hands. In this process the device will encounter different barrier. All comes unpredictable. So if we don't complete this experiment, our device will not finish the work in fully items. Drop test is necessary.

Rolling test

The rolling test carries out on closed environment. Rolling box is irregular shape like two trapezoids combined together. The rolling box can scroll the device up and down. If your device is not stronger enough, it can not pass the test. It can inspect the screen and shell. Some devices will have screen crack or other damages. Rolling test is very cruel than other tests.

Waterproof test

The device need to stay at water to evince it is water – resistance. The experiment standard is very rigid. We keep the device on operating status for several days below 1.5~1.8 meters water. Only after this rigid test, its quality and mechanical design was approved to operating in some extreme environment and conditions. Obviously, nothing to worry when device drops into water carelessly or provides serving in torrential rains.

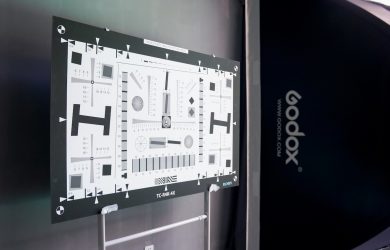

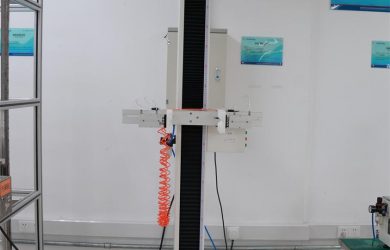

Camera test

The light box can spray different colors and temperature light sources. Projection light box can test the camera brightness uniformity. The machine can test the camera resolution. It can complete the high demands work. The camera can accept the light brightness to change the details.